Traxxas "Magnum" Transmission the Snake Eyes Racing Way

#1

************************************************** **********

I'm adding this part to explain myself after the feed back I have gotten. In no means I'm I saying you have to do this or that the RPM part is bad.

I did all this work for a few reasons.

#1: I have done this for 15 some odd years with my Stampede and Rustler trucks. Doing it kept the motor from moving and melting the mount in the days before aftermarket case where hanging up in the hobby shop. I would have loved that trust me! I have gotten to a point that it is the only way I run them. It's normal to me.

#2 I do not like the way the stock or RPM motor mount adjusts. I raced Losi's and found I like the two long slot adjusters over the one hole one slot of the stock and RPM types.

#3 The full motor plate of the Losi and Blue Eagle parts give strength in the event of a hard hit coming off a jump or if slid backwards into a wall or other hard object.

#4 Going off number 3. When coming off a jump I would trouble with the plastic flexing and eating spur gears. All this fixed that for good.

#5 By doing all this it has allowed me to move the center line of the motor closer to that of the truck. A Losi XX "cr" thing. This helps keep the truck from twisting there for it runs and flys truer.

#6 The ATF. I come from a background of full size cars as well. You don't run them dry, why would I run this dry. The scale loads are the same or higher.

Now why post this?

Well little old school knowledge can be a good thing. Most of us do learn from what we read or see. You do have to read it however to understand it. That means all of it.

I ask, how do you think I the cool parts list in the posts bashing me come to be? They just showed like Santa made them just for you. I bet not. Someone like me had to be crazy enough to make and try something different. Unless they steal it from someone just trying help others have more fun with there toys and make money. It's sad that someone with an open-mind to new things, even if this old for me, has to explain themselves to so many close-minded people in the world.

I started this in High School (class of '01) The last update was 2010 sometime when I added my 1:1 cars. So all old stuff.

Snake Eyes Racing

So, your welcome.

Please, if you want this to go away as "useless" just don't post a replay. Simple. 1/29/2018

************************************************** *

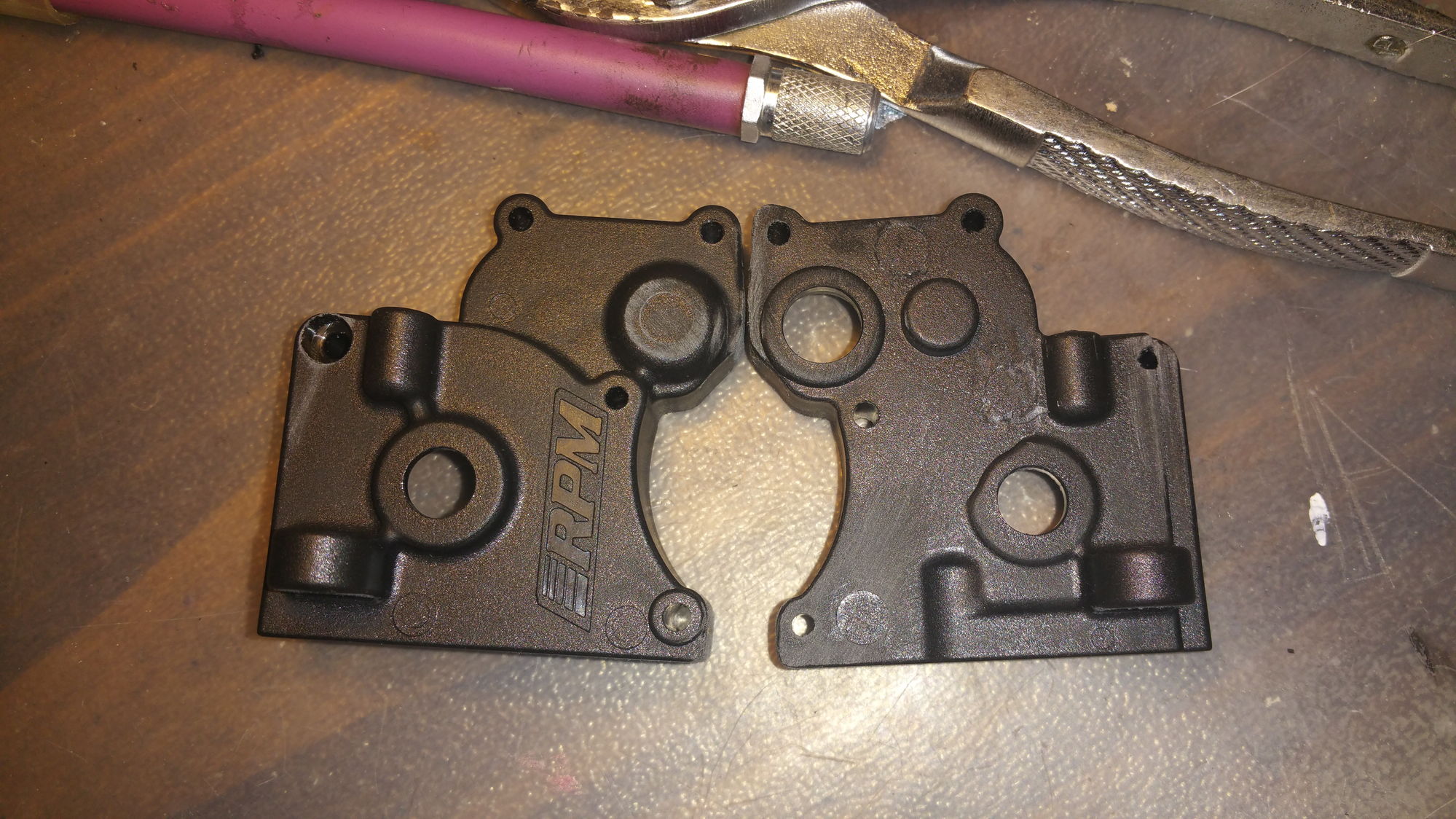

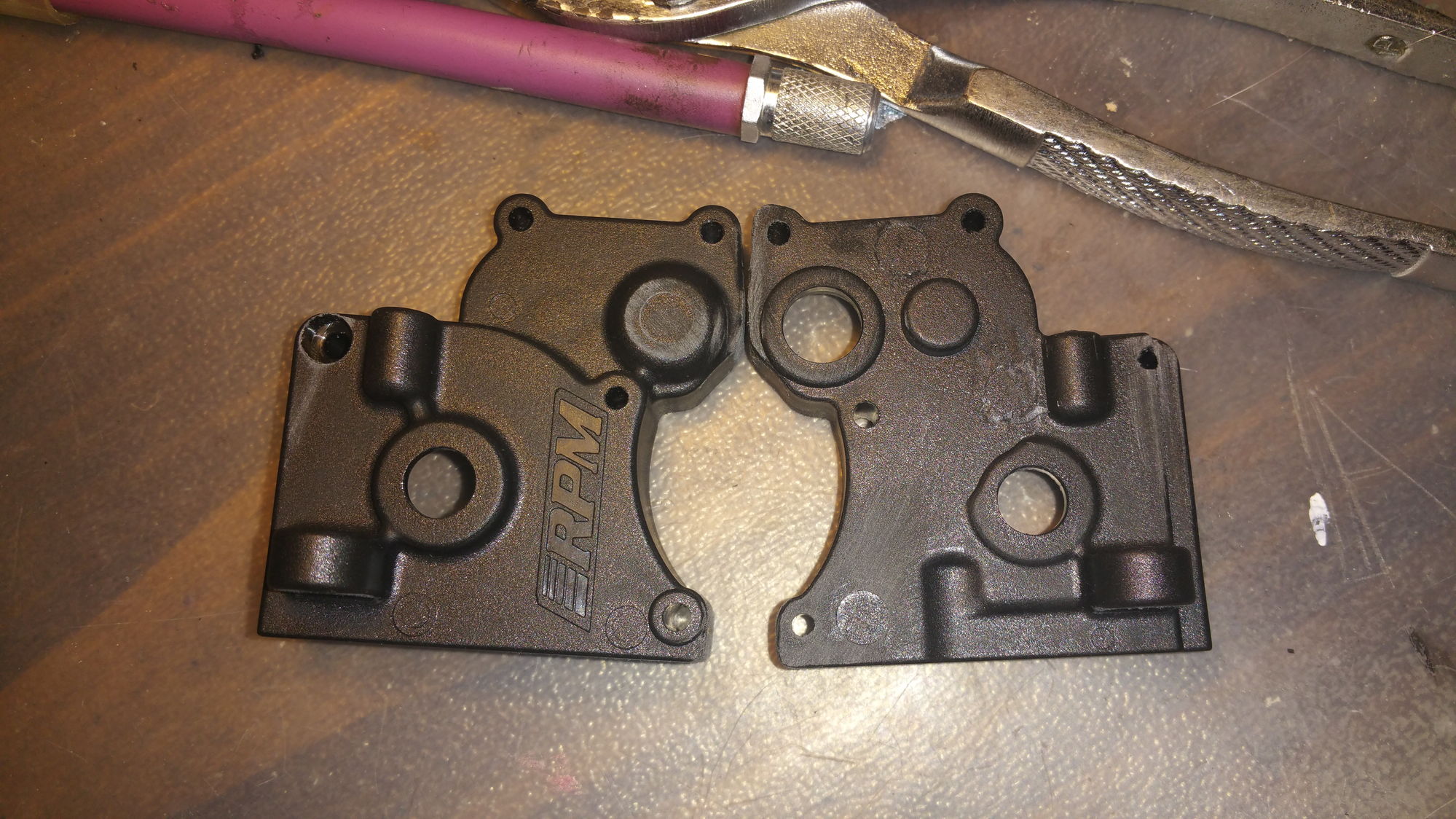

For these of you with Stampedes', Rustlers', Bandits' and, Slashes this uses the RPM case and a solid full motor plate for the best of all things. Do note, you will need to find new ways to mount wheelie bars and rear bumper if you use this.

If you run a RPM case now or plan to soon but you don't want to go through all this to make it work right, see post #2

Silver lines mark where to cut.

All cut and ready for new holes for the motor plate.

A total of five 4-40 screws hold the motor plate on. Two from the inside to keep the plate on when the trans is apart for maintenance and the three upper most factory holes with long screws. Like the TRX Blue Eagle motor plate. Fill plug for ATF on top and level plug by the R in RPM on the side.

Two 4-40 holes added to front of case to keep haves together and give more support to the case. They also serve as drain plugs for the ATF. Two blue screws on lower part of the motor plate are ran from in the case. Button heads where used for low profile.

Good look at the Thorp topshaft from the '90s. Silver circle indicates where centering bump on case is. This is also where the idler gear is in the case. Silver arrows, if you can see them, are mounting bolts for plate to case.

Spacers are used to help center the motor closer to the center line of the truck and are glued to the case to keep them in place. You can also see the AE VTS slipper.

Side notes and other things that where done:

Removed flashing and there was a lot of it.

Sanded the diff bearing recess deeper on both sides to let bearing seat flush with the inside of the case. This had to be done to get the case to close. No shims on diff outputs.

One shim each side of top shaft.

One thick shim on slipper side of idler gear to center it to the diff better. No room for one on the other side as idler shaft mount will need sanded down to do so. That will be done next service.

Ultra Black RTV to seal the case from dirt and keep the ATF in.

Do not over tighten screws as it will bind the trans. Even the arm mounts.

Most holes in case are for larger than 4-40 screws so stock like hardware will need to be used anywhere screws do not go into motor plate.

The motor plate used here is a Losi XX series black plate. A Traxxas Blue Eagle plate is a near direct fit for this as well. The RPM plate uses most of that plate as a template from the looks of it.

Gears used are Traxxas steel top shaft gear, Traxxas Alum. Idler gear and, Traxxas steel ring gear diff case.

Diff is packed with automotive wheel bearing grease.

If you wish to run it without spacers, you will need to drill a 23/64th or 3/8 hole in the plate for the locator bump.

I think that's most of it. PM me or post if you have questions. Updates if needed will follow.

Thank You for looking. Copyright 2018 Jessica King.

I'm adding this part to explain myself after the feed back I have gotten. In no means I'm I saying you have to do this or that the RPM part is bad.

I did all this work for a few reasons.

#1: I have done this for 15 some odd years with my Stampede and Rustler trucks. Doing it kept the motor from moving and melting the mount in the days before aftermarket case where hanging up in the hobby shop. I would have loved that trust me! I have gotten to a point that it is the only way I run them. It's normal to me.

#2 I do not like the way the stock or RPM motor mount adjusts. I raced Losi's and found I like the two long slot adjusters over the one hole one slot of the stock and RPM types.

#3 The full motor plate of the Losi and Blue Eagle parts give strength in the event of a hard hit coming off a jump or if slid backwards into a wall or other hard object.

#4 Going off number 3. When coming off a jump I would trouble with the plastic flexing and eating spur gears. All this fixed that for good.

#5 By doing all this it has allowed me to move the center line of the motor closer to that of the truck. A Losi XX "cr" thing. This helps keep the truck from twisting there for it runs and flys truer.

#6 The ATF. I come from a background of full size cars as well. You don't run them dry, why would I run this dry. The scale loads are the same or higher.

Now why post this?

Well little old school knowledge can be a good thing. Most of us do learn from what we read or see. You do have to read it however to understand it. That means all of it.

I ask, how do you think I the cool parts list in the posts bashing me come to be? They just showed like Santa made them just for you. I bet not. Someone like me had to be crazy enough to make and try something different. Unless they steal it from someone just trying help others have more fun with there toys and make money. It's sad that someone with an open-mind to new things, even if this old for me, has to explain themselves to so many close-minded people in the world.

I started this in High School (class of '01) The last update was 2010 sometime when I added my 1:1 cars. So all old stuff.

Snake Eyes Racing

So, your welcome.

Please, if you want this to go away as "useless" just don't post a replay. Simple. 1/29/2018

************************************************** *

For these of you with Stampedes', Rustlers', Bandits' and, Slashes this uses the RPM case and a solid full motor plate for the best of all things. Do note, you will need to find new ways to mount wheelie bars and rear bumper if you use this.

If you run a RPM case now or plan to soon but you don't want to go through all this to make it work right, see post #2

Silver lines mark where to cut.

All cut and ready for new holes for the motor plate.

A total of five 4-40 screws hold the motor plate on. Two from the inside to keep the plate on when the trans is apart for maintenance and the three upper most factory holes with long screws. Like the TRX Blue Eagle motor plate. Fill plug for ATF on top and level plug by the R in RPM on the side.

Two 4-40 holes added to front of case to keep haves together and give more support to the case. They also serve as drain plugs for the ATF. Two blue screws on lower part of the motor plate are ran from in the case. Button heads where used for low profile.

Good look at the Thorp topshaft from the '90s. Silver circle indicates where centering bump on case is. This is also where the idler gear is in the case. Silver arrows, if you can see them, are mounting bolts for plate to case.

Spacers are used to help center the motor closer to the center line of the truck and are glued to the case to keep them in place. You can also see the AE VTS slipper.

Side notes and other things that where done:

Removed flashing and there was a lot of it.

Sanded the diff bearing recess deeper on both sides to let bearing seat flush with the inside of the case. This had to be done to get the case to close. No shims on diff outputs.

One shim each side of top shaft.

One thick shim on slipper side of idler gear to center it to the diff better. No room for one on the other side as idler shaft mount will need sanded down to do so. That will be done next service.

Ultra Black RTV to seal the case from dirt and keep the ATF in.

Do not over tighten screws as it will bind the trans. Even the arm mounts.

Most holes in case are for larger than 4-40 screws so stock like hardware will need to be used anywhere screws do not go into motor plate.

The motor plate used here is a Losi XX series black plate. A Traxxas Blue Eagle plate is a near direct fit for this as well. The RPM plate uses most of that plate as a template from the looks of it.

Gears used are Traxxas steel top shaft gear, Traxxas Alum. Idler gear and, Traxxas steel ring gear diff case.

Diff is packed with automotive wheel bearing grease.

If you wish to run it without spacers, you will need to drill a 23/64th or 3/8 hole in the plate for the locator bump.

I think that's most of it. PM me or post if you have questions. Updates if needed will follow.

Thank You for looking. Copyright 2018 Jessica King.

Last edited by SocalSnakeEyes; 01-29-2018 at 02:20 PM.

#2

If running the RPM case as delivered you will still want too:

Remove flashing and there was a lot of it.

Sand the diff bearing recess deeper on both sides to let bearing seat flush with the inside of the case. This had to be done to get the case to close. No shims on diff outputs.

Use Ultra Black RTV to seal the case from dirt.

Sand off part of the case that touches the skid plate so the bolt holes line up.

Hope this helps. Have fun with your "toys".

Remove flashing and there was a lot of it.

Sand the diff bearing recess deeper on both sides to let bearing seat flush with the inside of the case. This had to be done to get the case to close. No shims on diff outputs.

Use Ultra Black RTV to seal the case from dirt.

Sand off part of the case that touches the skid plate so the bolt holes line up.

Hope this helps. Have fun with your "toys".

Last edited by SocalSnakeEyes; 01-25-2018 at 05:18 PM.

#3

So much work for something that isnt really needed?

The RPM case already comes with a metal motor plate. From there add a Hot Racing sealed diff and the STRC slipper conversion. Also, why fill it with ATF? I have run them dry for years with no ill effects.

I run the stock Traxxas case, Proline motor screws/washers, 32p conversion, Hot Racing sealed diff w/ 50,000 fluid in my Slash 2wd and its just about perfect for racing.

The RPM case with the metal motor mount and AE conversion would be the only upgrades on top of what I already have. And on top of that I can keep my rear bumper mounts and dont need to fashion something up.

And don't use that aluminum idler gear. It shreds faster than the factory steel gear.

The RPM case already comes with a metal motor plate. From there add a Hot Racing sealed diff and the STRC slipper conversion. Also, why fill it with ATF? I have run them dry for years with no ill effects.

I run the stock Traxxas case, Proline motor screws/washers, 32p conversion, Hot Racing sealed diff w/ 50,000 fluid in my Slash 2wd and its just about perfect for racing.

The RPM case with the metal motor mount and AE conversion would be the only upgrades on top of what I already have. And on top of that I can keep my rear bumper mounts and dont need to fashion something up.

And don't use that aluminum idler gear. It shreds faster than the factory steel gear.

#5

FYI, the ATF is going to rob horsepower, shorten the life of your motor, and generate more heat.

#6

Tech Master

iTrader: (121)

My question about the ATF is how do you keep it from running out of the out drive bearings? I know that when a diff starts leaking in one of my 8th scales, I know it because the fluid starts running out past the bearings. I would imagine something as thin as ATF would pour out pretty fast.

#7

The answer from your Traxxas forum post is:

Metal on metal tends to eat things. A little ATF will cut down on that. I should be able to go longer between rebuilds this way too. There is about a half oz in it. Just to keep things slick and clean. After 10 packs or it brakes what ever comes first I will take it apart and see how everything is. Four packs from now I will drain it just to have a look at the fluid. That will tell me how things are going inside. Later I plan to put a magnet in there to collect any metal that wares off as it is ran.

My question about the ATF is how do you keep it from running out of the out drive bearings? I know that when a diff starts leaking in one of my 8th scales, I know it because the fluid starts running out past the bearings. I would imagine something as thin as ATF would pour out pretty fast.

Truth be told I'm more worried it will thin the grease in the diff.

Last edited by SocalSnakeEyes; 01-26-2018 at 10:56 PM.

#8

Almost forgot. The fluid will help take up the slack in the gears cutting down on gear wear because they are not banging in to each other but rather riding on the oil that is on the gears. Some as with old hot rods running a 15-50 racing motor and not a 0-20 like new car that have small clearances between there rod bearings, lifters and, valves that work the cyl cutoff systems.

I wouldn't use it in all RC transmissions but for these I have yet to see any parts brake because of it. My old Losi race trucks I just put a thin coat of Marvel Mystery Oil on only the idler. It is thinner then ATF and works better with the better made gears in the race trucks. The trucks were quieter and quicker with it in there. Of course that was in the days of plastic gears.

Call me crazy if you want however I have had a lot of time to try things in my 24 years of playing with RC cars and almost as long with full size cars.

I wouldn't use it in all RC transmissions but for these I have yet to see any parts brake because of it. My old Losi race trucks I just put a thin coat of Marvel Mystery Oil on only the idler. It is thinner then ATF and works better with the better made gears in the race trucks. The trucks were quieter and quicker with it in there. Of course that was in the days of plastic gears.

Call me crazy if you want however I have had a lot of time to try things in my 24 years of playing with RC cars and almost as long with full size cars.

Last edited by SocalSnakeEyes; 01-26-2018 at 11:33 PM.

#9

re talking to a "youngin" every time you get on a computer. Some of us have been around the hobby for quite a while.

Im glad you made something. Pat on the back. We used to "make stuff on our own" when there was nothing on the market to use. Everything you have done already has a better designed and cleaner fabricated option on the market. You literally cut apart an RPM case that already has a metal motor plate. Then you go and add ATF to it? Tamiya AW grease would be optimal if you wanted to reduce friction in the case.

This is a forum where people can call out others for a waste of time. If you dont like our rebuttal posting then dont post crap info to begin with.

Good luck with your "transmission".

#10

No one can tell anyone else that they are wasting their time. It's their time to do with as they please. I'd rather see stuff like this as opposed to repetitive questions about setup sheets by people too lazy to learn how to tune a car.

#11

So much work for something that isnt really needed?

The RPM case already comes with a metal motor plate. From there add a Hot Racing sealed diff and the STRC slipper conversion. Also, why fill it with ATF? I have run them dry for years with no ill effects.

I run the stock Traxxas case, Proline motor screws/washers, 32p conversion, Hot Racing sealed diff w/ 50,000 fluid in my Slash 2wd and its just about perfect for racing.

The RPM case with the metal motor mount and AE conversion would be the only upgrades on top of what I already have. And on top of that I can keep my rear bumper mounts and dont need to fashion something up.

And don't use that aluminum idler gear. It shreds faster than the factory steel gear.

The RPM case already comes with a metal motor plate. From there add a Hot Racing sealed diff and the STRC slipper conversion. Also, why fill it with ATF? I have run them dry for years with no ill effects.

I run the stock Traxxas case, Proline motor screws/washers, 32p conversion, Hot Racing sealed diff w/ 50,000 fluid in my Slash 2wd and its just about perfect for racing.

The RPM case with the metal motor mount and AE conversion would be the only upgrades on top of what I already have. And on top of that I can keep my rear bumper mounts and dont need to fashion something up.

And don't use that aluminum idler gear. It shreds faster than the factory steel gear.

#12

All oils maintain a film that prevents moving parts from directly contacting each other, at least until the oil is subjected to such high pressure that the microscopic film gets crushed out from between the parts. That is not a unique property of ATF. Anyway, most RC transmissions will fail for other reasons before the gears can be that heavily-loaded.

The unique property of ATF is: It's formulated to be extremely sticky when compressed into a microscopic film, because that's necessary for the clutches and brake-bands inside automatic transmissions to work properly. Without an oil that gets sticky when compressed into a microscopic film, those parts would slip under the kind of horsepower modern engines can generate.

That stickiness of ATF doesn't have any helpful application in RC, since RC transmissions don't have any parts that stay in-place by pressure alone. (except ball-diffs, but ATF would fling out of ball-diffs too easily.)

I use AquaCraft Grim Racer marine grease in my gearboxes. It's plenty slippery, it lasts forever, and I have transmissions several years old that show no wear except for light polishing of the gear teeth.

The unique property of ATF is: It's formulated to be extremely sticky when compressed into a microscopic film, because that's necessary for the clutches and brake-bands inside automatic transmissions to work properly. Without an oil that gets sticky when compressed into a microscopic film, those parts would slip under the kind of horsepower modern engines can generate.

That stickiness of ATF doesn't have any helpful application in RC, since RC transmissions don't have any parts that stay in-place by pressure alone. (except ball-diffs, but ATF would fling out of ball-diffs too easily.)

I use AquaCraft Grim Racer marine grease in my gearboxes. It's plenty slippery, it lasts forever, and I have transmissions several years old that show no wear except for light polishing of the gear teeth.

#14

Generally speaking I agree. A lot of my projects qualify as a waste of time if the sole metric for worthwhileness is performance on a racetrack. However, I try to have a describable purpose in-mind with all my projects, and in this case I'm puzzled about what the purpose is. Experimenting with different kinds of lubricants is fun sometimes, but as for the motor-plate mod...the RPM gearbox already comes with a metal motor plate, so what's the benefit of hacking it up to use a metal motor plate from a different vehicle? It seems like a lot of work to achieve the exact same result as stock.

#15

The STRC topshaft conversion is also a very good upgrade, but the Associated slipper clutch fits on that topshaft as well, so if she has an older part that works the same, there's no reason to buy a new part instead. As for the VTS add-on, whether or not you need that really boils down to whether you can get the tightness you need from the normal 2-pad slipper clutch without bottoming-out the spring. Using the SC10 spring makes that a lot easier, because it's much firmer than the RC10 spring. Still, one of my trucks with an Associated slipper clutch conversion did need the VTS add-on, because even with the stiffer SC10 spring I still had to bottom-out the spring to keep the spur gear from slipping like crazy.

15Likes

15Likes