Can someone Vacuum a Shell for me?

#1

Tech Regular

Thread Starter

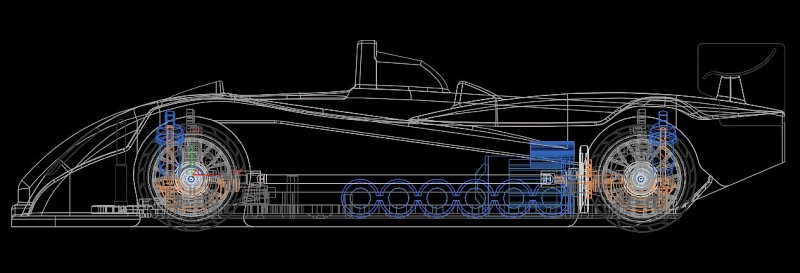

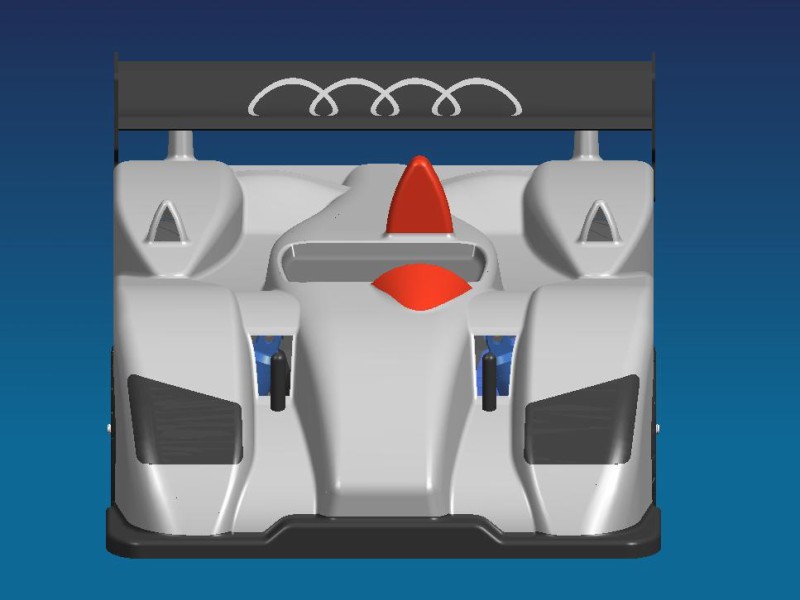

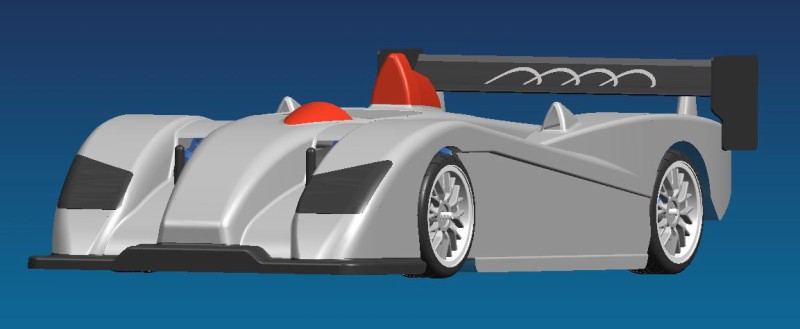

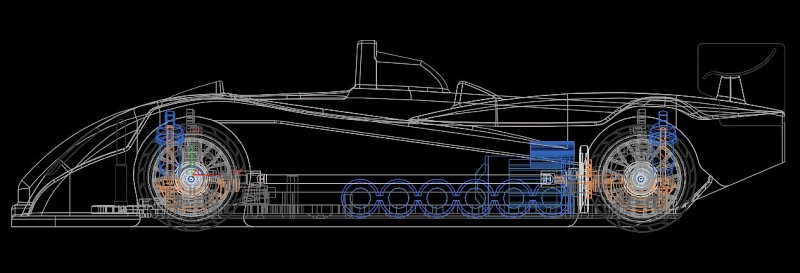

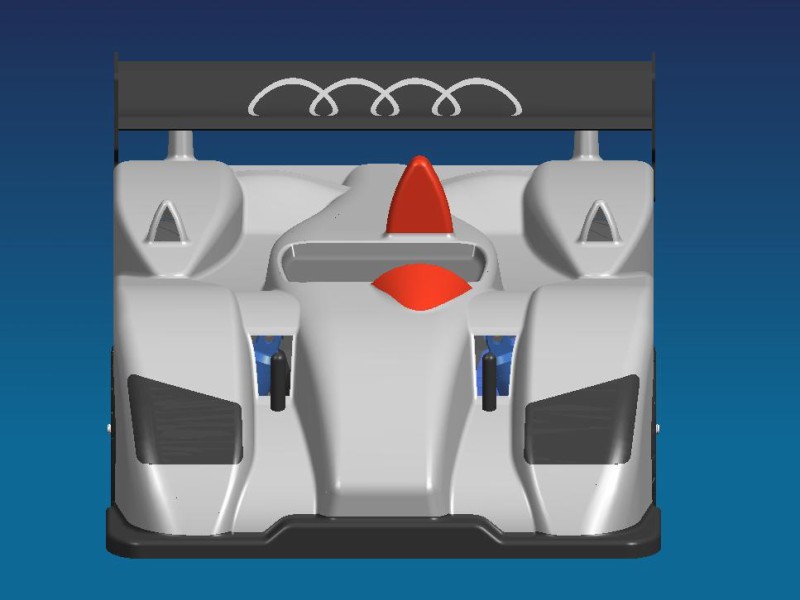

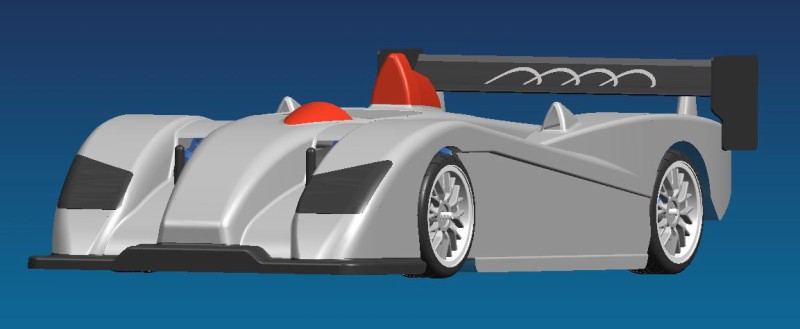

I'd been looking for a LeMans-type shell for touring cars for a while and finally decided to just make one myself. I've come up with a design that should fit most TC's on the market, and have the resources to make a mold of the design, but need someone with vacuum forming experience to pull some shells for me.

Can anyone direct me to someone who does vacuum forming work?

Here are a few pics of the shell...

http://images16.fotki.com/v302/photo...di_R807-vi.jpg

http://images16.fotki.com/v3/photos/...di_R803-vi.jpg

http://images15.fotki.com/v229/photo...di_R802-vi.jpg

Can anyone direct me to someone who does vacuum forming work?

Here are a few pics of the shell...

http://images16.fotki.com/v302/photo...di_R807-vi.jpg

http://images16.fotki.com/v3/photos/...di_R803-vi.jpg

http://images15.fotki.com/v229/photo...di_R802-vi.jpg

Last edited by SammyXp; 05-31-2006 at 10:33 AM.

#3

Tech Addict

Contact Josh Cyrul. I think he could probably do that for ya. www.cefx.net

There's a thread on rctech somewhere about how to make a vacuum forming machine. Basically, you just need to build the box with some form of screen on the top of the bottom half, then use thumb screws or wing nuts to secure the top ring. Just use a strong shop vac to pull the heated lexan into shape over your mold. It's not perfect, but it does work in a pinch.

There's a thread on rctech somewhere about how to make a vacuum forming machine. Basically, you just need to build the box with some form of screen on the top of the bottom half, then use thumb screws or wing nuts to secure the top ring. Just use a strong shop vac to pull the heated lexan into shape over your mold. It's not perfect, but it does work in a pinch.

#4

Tech Regular

Thread Starter

Originally Posted by RcCzarOfOld

Contact Josh Cyrul. I think he could probably do that for ya. www.cefx.net

There's a thread on rctech somewhere about how to make a vacuum forming machine. Basically, you just need to build the box with some form of screen on the top of the bottom half, then use thumb screws or wing nuts to secure the top ring. Just use a strong shop vac to pull the heated lexan into shape over your mold. It's not perfect, but it does work in a pinch.

There's a thread on rctech somewhere about how to make a vacuum forming machine. Basically, you just need to build the box with some form of screen on the top of the bottom half, then use thumb screws or wing nuts to secure the top ring. Just use a strong shop vac to pull the heated lexan into shape over your mold. It's not perfect, but it does work in a pinch.

The hardest part in fitting the Audi R8 to a touring car were the shock towers. The R8 doesn't have those vents up front, in between the fenders and cockpit. I put them in to clear the shock towers on my TC3. I'm hoping all touring cars have shock towers in similar locations or else people are going to have to cut clearance holes and have their shocks poke through the body.

Same in the back, where I put in those bulges. Interrupts the aero flow, definitely, but LeMans type shells usually aren't high-speed bodies. Ton of downforce for small tracks, or for when horsepower is aplenty (Brushless/LiPo).

It is a little bit long as far as 190mm shells go. Right under 17.5".

#5

Tech Addict

On the rear tower clearance area that you have raised.. Have you tried making it a longer angle to minimize the disruption in the air flow? Or would that reduce the benefit of the channeling effect of the area to nearly nothing? Once you get a few made, would you be able to do any aero testing on them?

Tony

Tony

#6

Tech Regular

Thread Starter

Originally Posted by RcCzarOfOld

On the rear tower clearance area that you have raised.. Have you tried making it a longer angle to minimize the disruption in the air flow? Or would that reduce the benefit of the channeling effect of the area to nearly nothing? Once you get a few made, would you be able to do any aero testing on them?

Tony

Tony

I don't have any means of doing actual aero testing, but I do have access to a Computational Fluid Dynamics software package at work that I've thought about running this thing through. I could get the theoretical center of pressure, net downforce/lift, and coefficient of drag. I'm worried about what I'll see with that rear shock tower hump. The front shock tower "vent" will probably just create a ton of frontal downforce, but the rear wing relies on laminar airflow approaching it and the shock tower hump isn't going to help that situation at all.

The center section of the real R8 actually dips down considerably. Probably to feed air to the rear diffuser and help it work more effectively, but undertrays and diffusers are illegal in RC racing, so I figured I'd raise the rear edge and form another element to the wing, directly on the bodyform.

This discussion is great. I want to refine the design as much as possible before releasing the file to rapid prototyping (after which, I'll only be able to make minor tweaks to the mold).

#7

Tech Addict

You will probably want to have the biggest wing you can put on there also. The body is going to have so much front downforce, you'll need it to balance it out. When you do get a few prototypes, I'd really like to test one out in our "experimental" class... Brushless, LiPo's, foam tires, etc... We have a nice bump just past the middle of the 150ish foot straight.. Caught air under the alfa at almost 50mph and went airborne... Really lookin for something to keep it on the ground.

#8

Tech Regular

Thread Starter

Yeah, looking at the wing profile in the first pic, it's probably pretty mild. I'll definitely max it out. One can always trim it down for more front end bite and less drag.

Your "experimental" class seems exactly the type of venue for this type of shell. I was hoping some of the big Lexan formers out there would eventually put out a LM shell for us, though.

Your "experimental" class seems exactly the type of venue for this type of shell. I was hoping some of the big Lexan formers out there would eventually put out a LM shell for us, though.

#9

Tech Addict

Yeah I'm quite suprised they haven't. With the speeds that mod touring cars are reaching now, door slammers just aren't quite cutting it anymore. When I "tap" another car on the straight and get air under the body and travel 20 feet down the straight about 4 feet in the air, it's bad... With the flat pan chassis that we run, a diffuser would be perfect. But, as you said, not legal.. blah.

Hurry up and get that thing done so I can be a SammyXP Bodies Team Driver

Tony

Hurry up and get that thing done so I can be a SammyXP Bodies Team Driver

Tony

#10

Tech Addict

I know it's not scale correct, but have you though about trying the same body canopied? Or something like the Toyota GT-1.. I would LOVE to find a race worthy version of that body in 190mm. But, I think you'd probably run into the same shock tower clearance issues you're having with the Audi.

Tony

Tony

#11

Tech Regular

Thread Starter

Actually, I have thought about taking artistic license and eliminating the open cockpit. I love the R8, but going with a canopy might help alleviate any licensing issues that could potentially creep up in the future. I'll try a new version with a canopy and see how it looks. Maybe call it a LM Crown Pleazer, or something.

#12

Tech Addict

Just call it "Le Mans V1.0"

Keep posting your progress here. I'm very interested to see how it turns out.

Tony

Keep posting your progress here. I'm very interested to see how it turns out.

Tony

#13

couldsom1 post up a link for a homemade vacume thingy?

thats a nice body man...i hope u can get it done ... maybe proline or sumthing might wana buy the design.....

thats a nice body man...i hope u can get it done ... maybe proline or sumthing might wana buy the design.....

#14

Tech Regular

Thread Starter

Originally Posted by ProudSavageOwnr

couldsom1 post up a link for a homemade vacume thingy?

thats a nice body man...i hope u can get it done ... maybe proline or sumthing might wana buy the design.....

thats a nice body man...i hope u can get it done ... maybe proline or sumthing might wana buy the design.....

There are dozens of good vacuum forming machine plans online, but here's one I liked in particular...

http://www.halloweenfear.com/vacuumformintro.html

#15

It's actually easier than you'd think to make your own vacuum former. I did it, and was actually making aftermarket bodies for the X-5 4 wheel drive buggy. but I couldn't keep up with some of the demand, and the cost Versus the profit wasn't enough to encourage further development.

I now have a real vacuum former at work, and am able to do small projects for myself! It's really handy! If you have any questions, I can help answer some!

I now have a real vacuum former at work, and am able to do small projects for myself! It's really handy! If you have any questions, I can help answer some!